Two Duke students are pushing the boundaries on modern medical technology by using three-dimensional printers to develop a new kind of prosthetic.

Seniors Richard Beckett-Ansa and Henry Warder are the co-founders of Duke's eNABLE chapter, a volunteer group that develops prosthetic tools using 3D printing resources. Students working with the club are currently developing two specialized prosthetics, one of which will go to Wake Forest resident Kaylyn McGuyrt. Unlike a typical prosthetic hand, Warder explained, the prosthetic that eNABLE is developing has more mechanical features, including exchangeable tools on the prosthetic that perform different functions.

“The potential is just absolutely unreal," Beckett-Ansa said. "I think that’s what drives me.”

The 26-year-old McGuyrt is a cake decorator for Sweet Traditions, a bakery in Wake Forest. Since she lost her arm in an ATV accident more than a year ago, McGuyrt said she has tried three different prosthetics, only one of which can be used functionally. She added that she has difficulties with certain job-specific tasks, such as using a rolling pin or opening large fridges.

“They’re really sweet. They’re very accommodating,” McGuyrt said of the eNABLE team. “I’m excited to see the final product.”

Red Hat, Inc. an open-source software company, played a key role in helping Beckett-Ansa and Warder fund the prosthetics that they have worked on so far. Red Hat recently awarded Duke’s Open-Source Pedagogy Research-Innovation program a $180,000 grant, some of which was allocated to eNABLE.

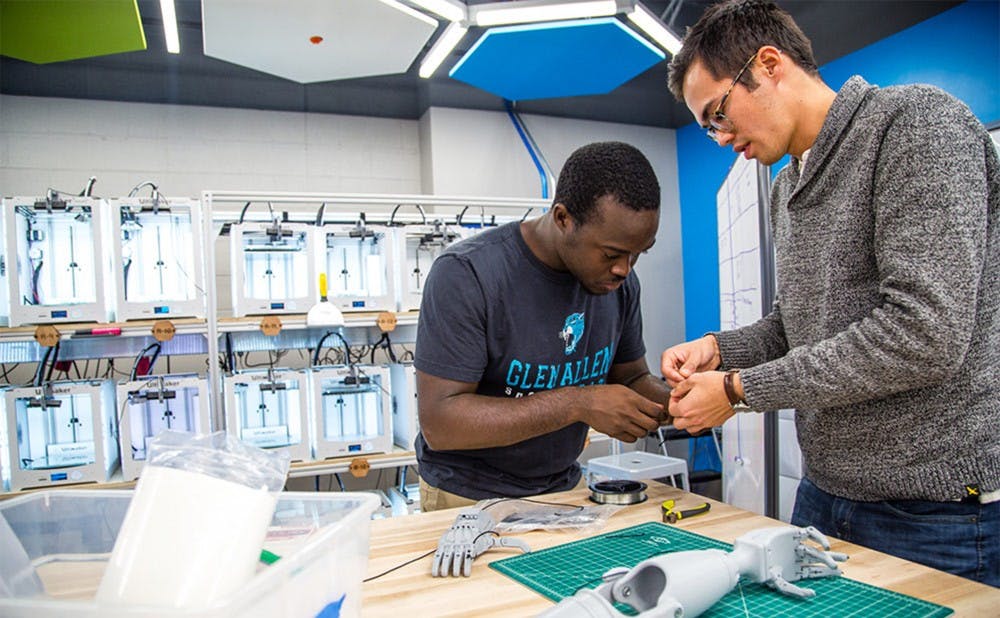

Currently, eNABLE is hosted in the Duke Innovation Co-Lab, which provides them with space and over 60 3D printers to use in their work. With 40 Ultimaker 2 printers alone, the Co-Lab is home to the highest concentration of these consumer 3D printers in the world—even more than the factory that assembles them, Warder noted.

“They just line the walls," Beckett-Ansa said. "It’s insane.”

Before starting Duke's eNABLE chapter, Beckett-Ansa and Warder had already developed significant 3D printing experience. In 2014, Beckett-Ansa worked at the University of Virginia's biomedical center and with its local eNABLE chapter, inspiring him to seek out a chapter for Duke. He soon began to collaborate with Warder, who first got involved in 3D printing through Duke Makers, the University's 3D printing club, and who had worked with a nonprofit prosthetics program in Ecuador with DukeEngage.

Duke eNABLE's current projects focus on building hands with functional attachments, Warder said. Looking forward, both he and Beckett-Ansa said they hope to continue their work in other limbs, such as legs.

As the field of 3D printing rapidly advances, especially in its applications to robotics and medicine, Duke and its students continue to invest in this technology.

“If it’s come this far in 10 years, I’d love to see where it’s going to be in 10 years,” Warder said.

Get The Chronicle straight to your inbox

Signup for our weekly newsletter. Cancel at any time.